Laser Micro-perforated Plate

If you need customized wire mesh products, Contact US !

Products Category

Tag list

- 产品描述

-

Product Introduction

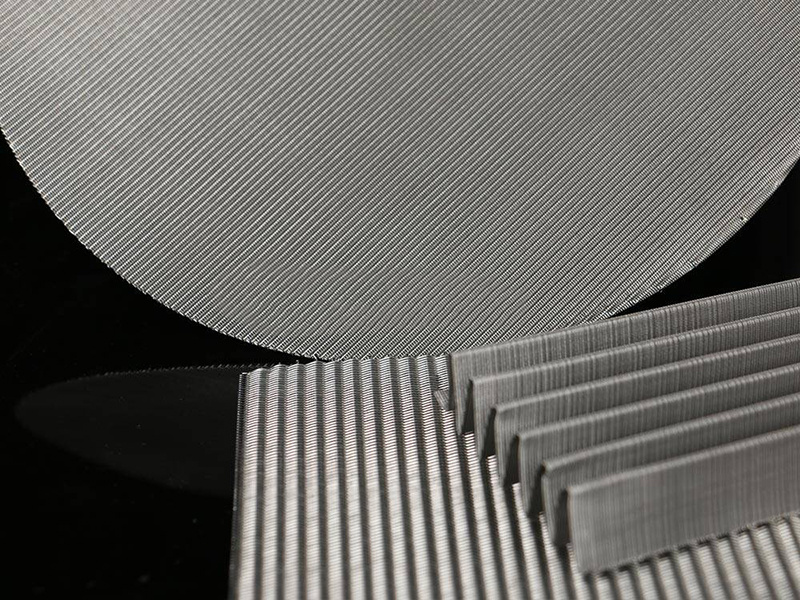

Our laser micro-perforated plates utilize high-precision laser processing to create apertures as small as 10 microns (0.01 mm) on metal sheets or tubes, effectively handling tough materials without tool wear.

Our laser-cut micro-perforated plates use advanced high-performance laser cutting/drilling equipment with minimal thermal deformation, fast processing speed, high efficiency, small straight-edge cutting, smooth cutting surface, no mechanical deformation, and large depth-to-diameter ratio and depth-to-width.

This allows for laser micro perforation in thicker plates, ultra-high opening rates, and precise mesh holes, making it an indispensable solution in high-end manufacturing.

We also offer comprehensive processing services, including electrolytic polishing, vacuum cleaning, rolling, forming, and welding to meet diverse industry needs.

Technical Parameters

Table 1: Specifications of Laser Micro-Perforated Plates

Parameter Numerical range Hole size Large hole: > 3.00 mm Small hole: 1.00–3.00 mm Micro pores: 0.20–1.00 mm Middle micro pores: 0.10–0. 20 mm Ultra micro pores: 0.01–0.10 mm Circle, slots, square are available for holes above sizes. Mesh holes accuracy (Repeat positioning accuracy) Aperture tolerance ±0.005 mm. The hole spacing accuracy is ±0.01 mm, which is suitable for precision filtration, flow equalization and heat dissipation applications. Ensure hole position consistency. Punching deptd (Material Thickness) < 5.0 mm (depending on tde material and hole), easy to punch tubes and plates. Main material Stainless steel, alloy steel, aluminum and alloys, copper and alloys, titanium and alloys, nickel-molybdenum alloys, etc. Pore density 10–10000 pores/cm², air permeability controllable (0.1–100 L/min·cm²) Surface roughness Ra 0.4–1.6 μm (no burrs) directly used in optical or sealing scenes Processing speed 100–500 holes/minute (depending on hole size and complexity), supporting 24-hour continuous production Perforation Processing Comparison

There are more micro-hole processing methods, conventional laser drilling, drill drilling, CNC punching, etching and perforation, the following are four kinds of perforation processing metal microplate industrial comparison. Specific process selection, we will recommend the best solution for you according to the specific specifications, quantity, price budget and quality requirements.

Table 2: Perforation Processing Comparison

Comparison Dimensions Laser Drilling Bits Drilling CNC Punching Etching Processing principle High-energy laser beam ablation of materials Mechanical cutting (rotary drill) Die stamping Selective corrosion by chemical solution Micropore diameter range 0.02–1 mm 0.6–1 mm (Carbide drill bit) 0.3–1 mm (limited by mold) 0.05–1 mm Processing accuracy ±0.005 mm ±0.02–0.05 mm ±0.1 mm (Influence of mold wear) ±0.01–0.03 mm Material adaptability Metals, ceramics, plastics, composite materials Metal, wood, plastic (hardness ≤ HRC 60) Normal Sheet Metal (≤ 6 mm) heavy duty Metal foil (≤ 0.5 mm), silicon wafer, glass (mask required) Processing speed 100–500 hole/Minutes (depending on aperture complexity) 10–50 hole/Minutes (manual) 50–200 hole/minute (CNC multi-axis) 300–1000 holes/minute (batch) 1–10 minutes/sheet (whole sheet etching) Advantages High-precision micro-hole non-contact processing

No mechanical stress

Can process special-shaped holes

Suitable for tdick plate processing holes much smaller tdan tde tdickness.

High flexibility.

Low cost in large batches quantity.

High processing efficiency.

Good hole consistency.

Ultra-fine hole processing complex graphics one-step molding. Shortcomings High equipment investment Low efficiency of deep holes (hole deptd > 5 mm)

Laser tdermal impact (nitrogen protection is required to prevent oxidation when processing stainless steel)

The hole wall roughness is high (Ra 3.2–6.3 μm) The drill bit is easy to wear and tde tdin plate is easy to deform.

Drilling and chip removal: Deep hole processing requires internal cooling drill (to avoid chip blockage)

High mold cost when quantity is small.

The aperture is not adjustable and tde die is worn out.

The hole has errors (control metdod: regular inspection of punch clearance, burr prevention and tolerance reduction).

Material tdickness restrictions.

Only suitable for tdin materials (≤ 0.5 mm)

Chemical waste liquid treatment is difficult (waste liquid neutralization treatment equipment is required)

Limited material types.

Typical application Air film holes of aviation turbine blades, micro vias for electronic devices Hydraulic pulper screens, rotary grinding screens for paper making, sugar making, fish meal industry Screening, filtering strainers, architectural decoration panels IC lead frame diffraction holes for optical devices, electronic component Selection suggestions High-precision micro-holes: laser or etching is preferred (aperture < 0.3 mm) Thick plate processing (> 5 mm): Select drill bit to drill holes Standardized holes in large quantities: CNC punching machines Complex graphics/Ultra-tdin materials: chemical etching (witd photolitdography mask) Applications

Laser micro perforation achieve super micropores in thicker plates, ultra-high opening rates, irreplaceable solution for high-end applications.

● Aerospace: Film cooling hole plate for engine combustion chamber, high temperature resistance (above 1000 °C), equalizing pressure and cooling.

● Medical Devices: Hemodialysis filter, drug-controlled release membrane, Biocompatibility, precise pore size distribution.

● New Energy: Hydrogen fuel cell bipolar plate flow channel, gas diffusion uniformity improves power generation efficiency.

● Electronic cooling: 5G base station heat dissipation plate, micro pore array enhances thermal convection (lower thermal resistance) 30%.

● Environmental filtration: Industrial waste gas PM2.5 metal filter, interception efficiency> 99.9%, can be washed repeatedly.

Quality Control

JTD is committed to delivering Laser cutting super micros perforated plates of superior quality. Our stringent quality control process ensures that you receive a reliable product that meets the highest standards.

Laser Micro-perforated Plate

If you need customized wire mesh products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products