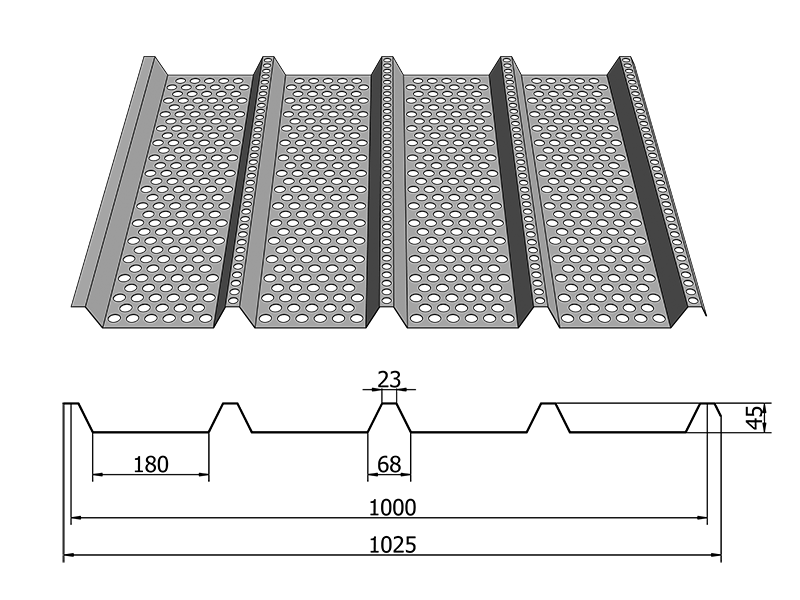

QSCP-T-45/248-1000

Corrugated Perforated Metal Panels

If you need customized wire mesh products, Contact US !

Products Category

Tag list

- 产品描述

-

Product Introduction

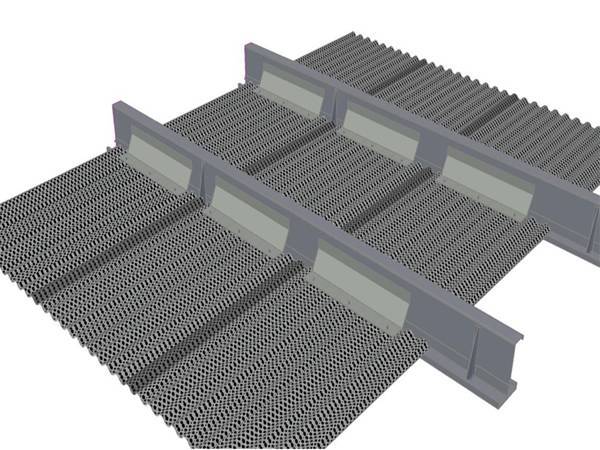

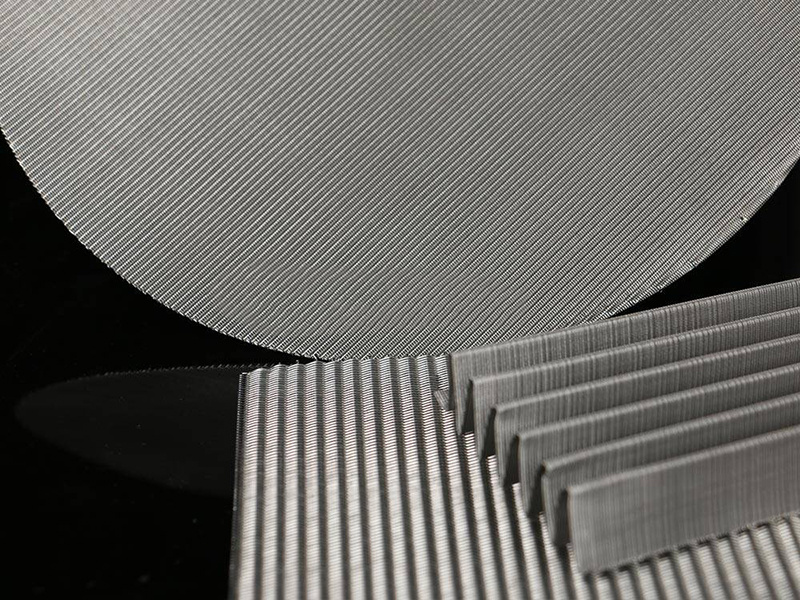

Corrugated perforated metal panel is the newest and most exciting product for architecture and industry application. As to Corrugated perforated panels, no matter it is basic or complex, standard or custom, we offer perforation patterns to suit any decorative or functional requirement.

Applications of Corrugated perforated panels include solar shading, light and sound, solution control, security screening, and screens for roof top mechanical equipment. Architects, engineers and design professionals often choose corrugated perforated metal for their building projects, used for Ceiling Panels, Architecture Facades and self-climbing safety platforms.

Here at we will be happy to help you with guidance in making your enquiry or original design.

Production Process

Basically, our production process for making corrugated perforated panels is as same as traditional perforated panels.

Firstly, punching perforated sheets by CNC punching machine by metal plates in sheet or metal plate in coils.

And then, we forming the perforated sheet into any profile or decorative panel of your choice by rolling forming machine or bending machine the perforated sheet.

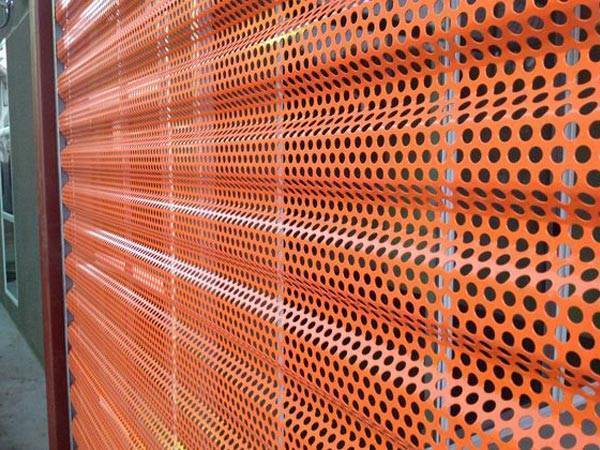

At last, if required, multiple surface finishing treatment options such as powder coating, fluorocarbon coating is available. There are UV resistant and various RAL color for different commercial and industrial applications for corrugated perforated metal panels.

Raw Material

Materials of perforated metal decides its performance in various industrial applications, we need to choose the right material for best performance and greatest advantage.

● Carbon Steel Plates. Q195, SPCC, Q235B

● Stainless Steel Plates. 304, 304L, 316, 316L,321,310S

● Aluminum Alloy Plates. 1060, 3003, 5052

● Pre-Galvanized Steel Plate

Surface Finishing

JTD offers multiple surface treatment options for different commercial and industrial applications for corrugated perforated metal panels.

● Powder coating

● PVDF coating

● Anodic oxidation

● And more surface treatment

Technical Parameters

Products Standards

● HOLES PATTERNS

Not limited, as same as plain perforated metal sheet.

● THICKNESS

As to rolling forming, thickness 0.3mm-1.0mm, aluminum plate can be 1.5mm thickness.

As to bending, thickness 0.3mm-5.0mm

● WIDTH

780mm, 840mm, 900mm, 910mm,1000mm and etc.

Rolling forming is one forming machine one width.

Bending forming can be customized the width.

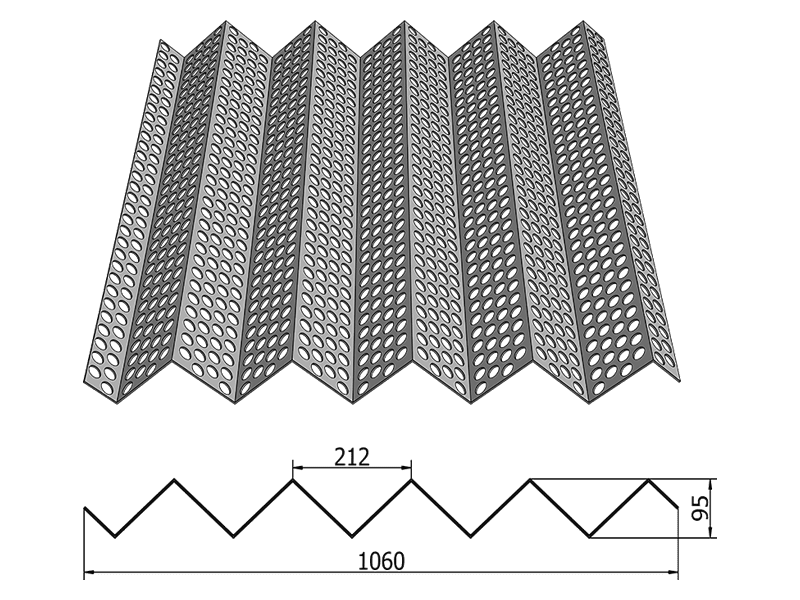

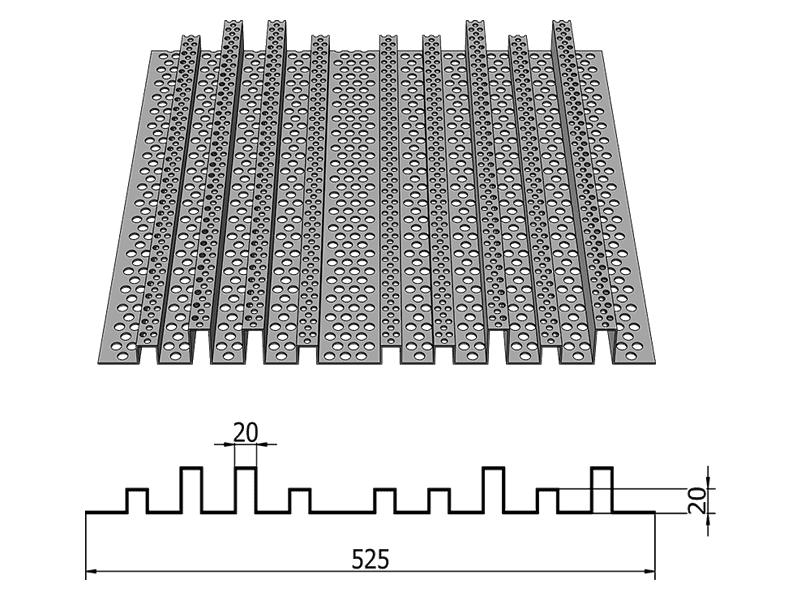

Notes: designing the Corrugated Section Profiles shall consider the raw material plate width limited and not wasting material

● LENGTH

Rolling forming Corrugated Perforated Metal length not limited, but due to container size, the length up to length 11.95meters.

Powder Coating perforated corrugated metal panels max length 10meters.Un-coating perforated corrugated metal panels max length 11.95meters.

Bending Corrugated Perforated Metal length can be 6meters length, probably up to 8meters depending on the material thickness, profiles and width.Sections Profiles

We will roll form or bend the perforated sheets into whatever profile or decking style panel your choosing &designing.

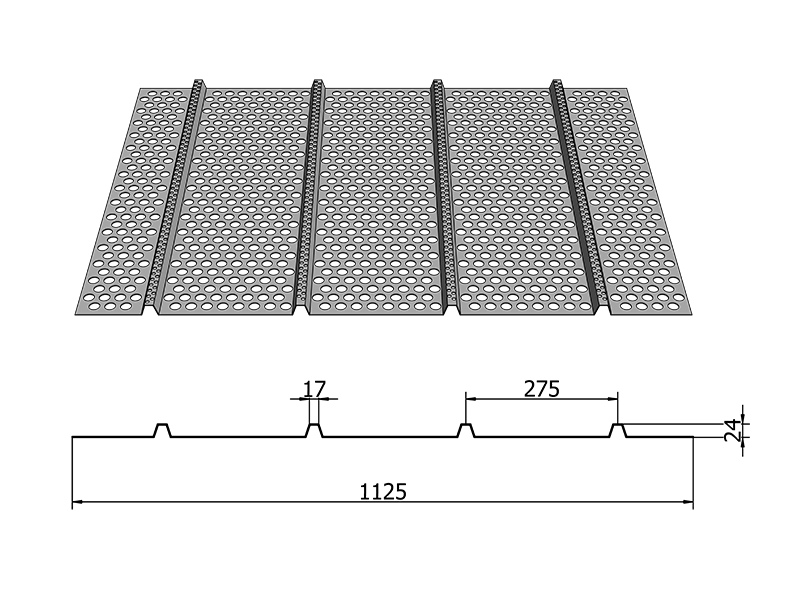

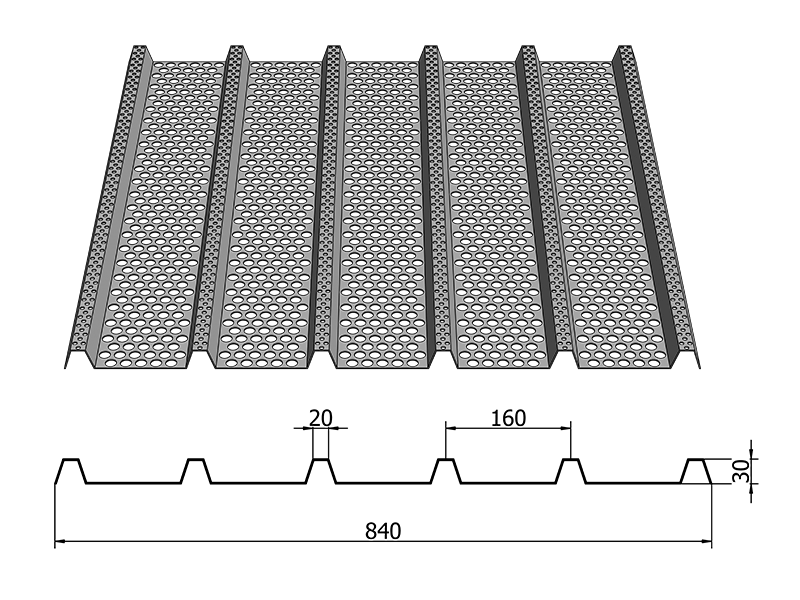

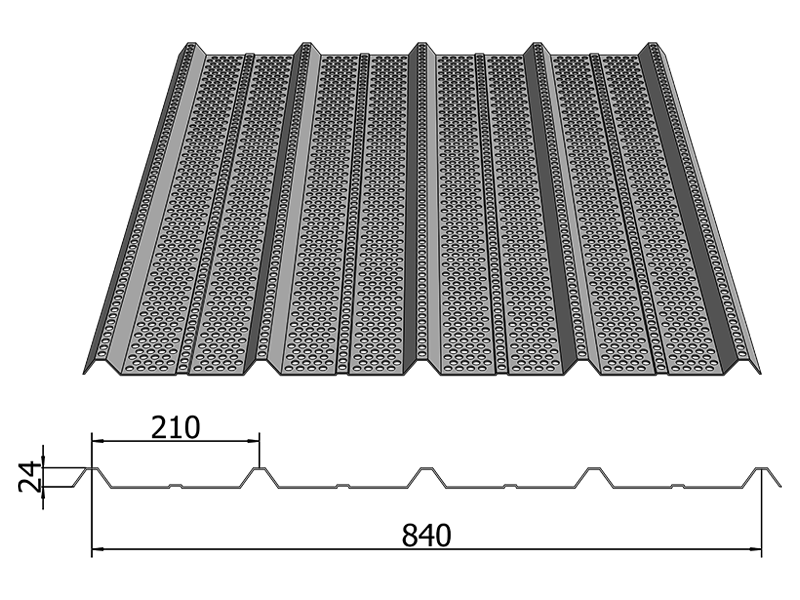

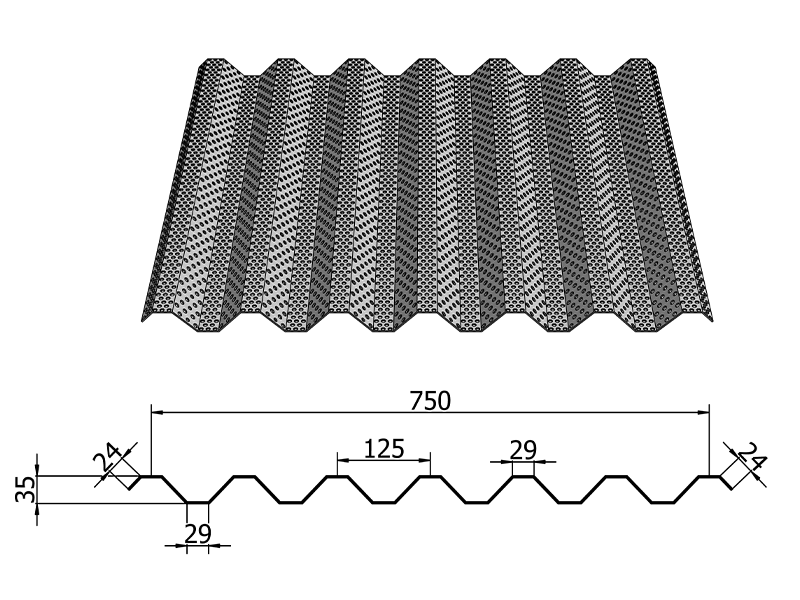

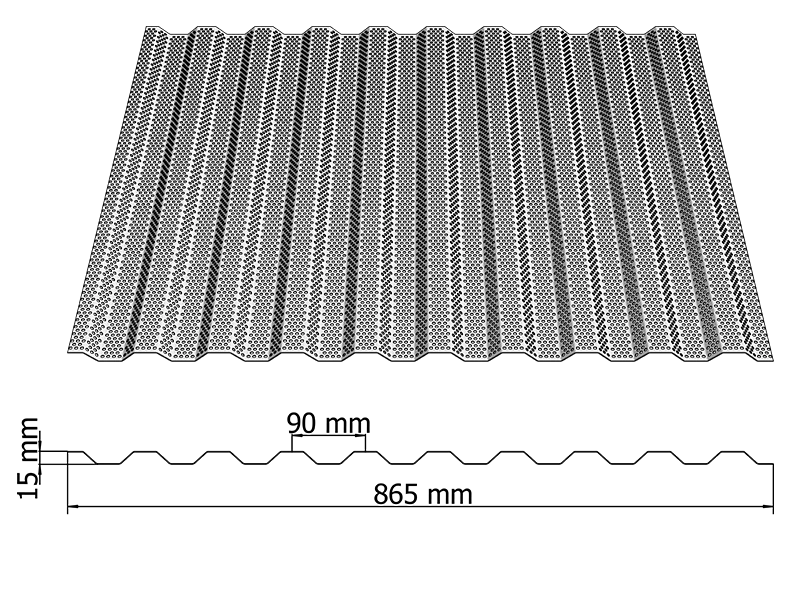

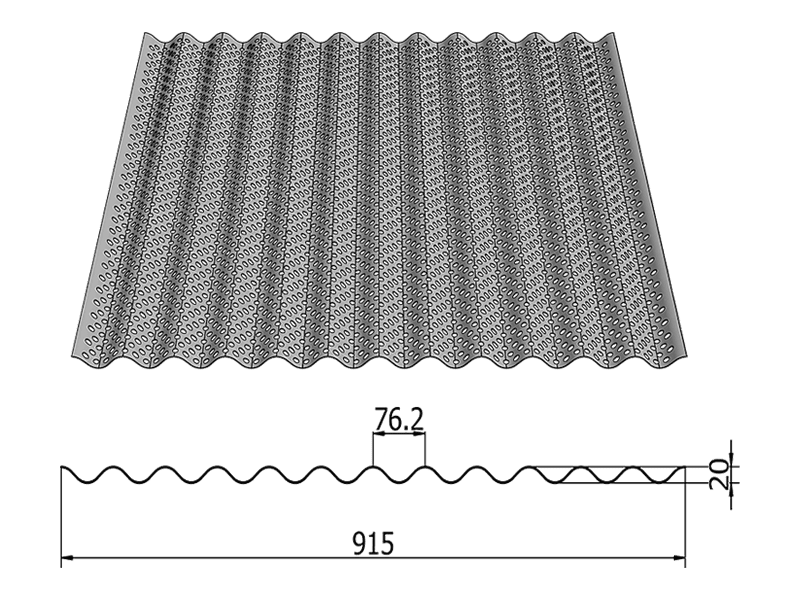

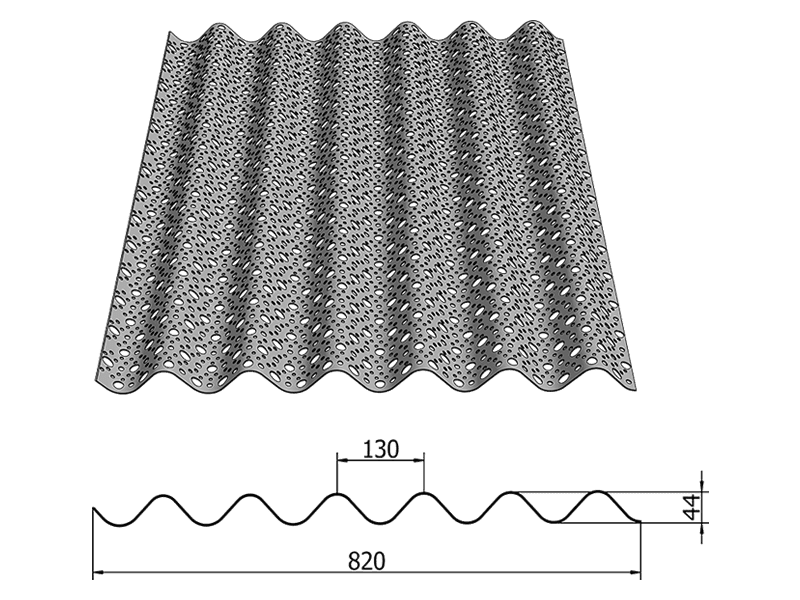

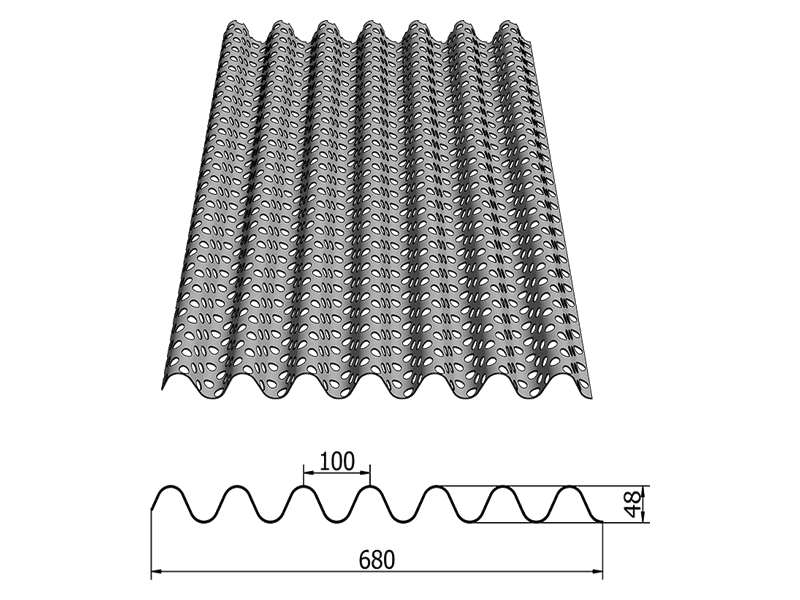

● Best-Selling Rolling Forming Perforated Corrugated Metal Plates

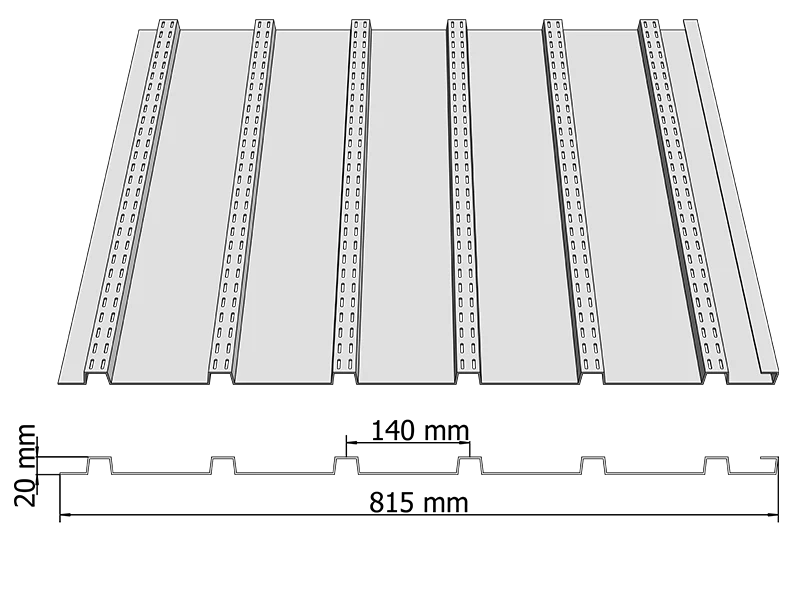

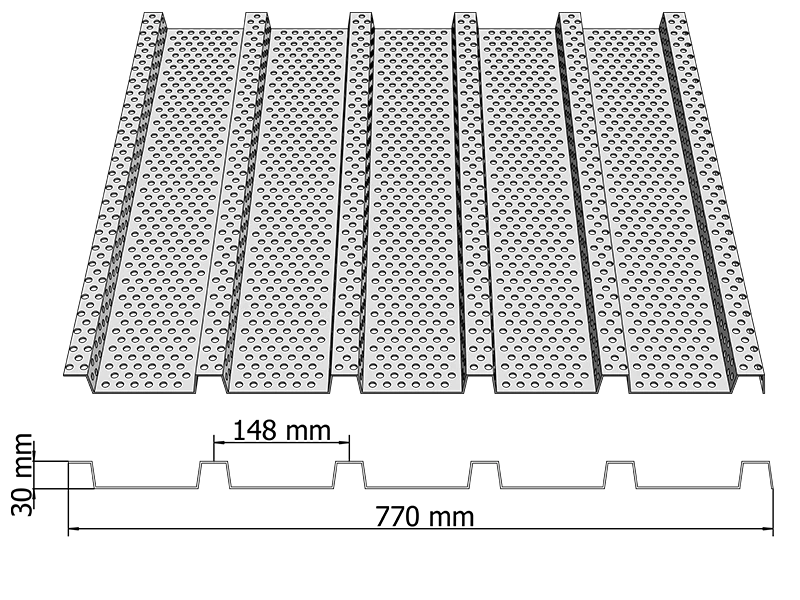

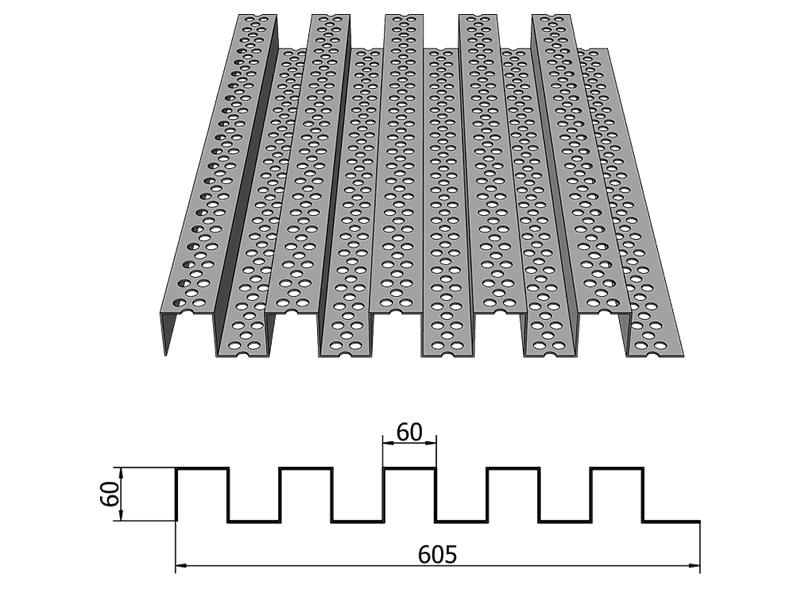

Well-Liked Bending Forming Perforated Corrugated Metal Plates

Advantages and Feature

Comparing with plain perforated metal sheet, corrugated Perforated metal sheet owns the following obvious advantages and features.

● Same thickness, higher strength

● Better wind protection

● Better sound insulation

● Creative designs and decorative performance

● Unique optical effect

Wonderful Applications

JTD provide high quality rolling forming or bending corrugated perforated sheet, there are many applications.

● Building and architectural decoration: It is used for exterior walls, ceilings, and partition walls as decorative materials to provide visual effects and air circulation.

● Filtration and screening: It is used in the industrial field as screening and filtering materials, such as screening ores in mining, and screening raw food materials in food processing.

● Acoustic control: It is used for acoustic insulation panels or sound-absorbing panels, which can be used to control noise and improve the acoustic environment.

● Cooling and ventilation: It is used for air conditioning equipment, ventilation systems, and radiators, providing air circulation and cooling effects.

● Safety protection: It is used to make safety railings, protective covers, etc., providing safety protection functions.WHY Choose Corrugated Perforated from JTD

More than 10 types rolling forming profiles machine on hand for your choice, no additional charges even if not too much order quantity.

Our advanced bending machine making your own individual profiles corrugated & perforated panel.

Customized rolling forming profiles or bending profiles shape &size are supportable for batch quantity.

Perforated hole patterns and styles are almost limitless. Hundreds of ready tooling molds, and our turret CNC punching, high speed CNCgantry punching, laser cutting bringing unlimited possibilities and low cost.

JTD owns the advanced technology powder coating and fluorocarbon coating production line to ensure finest surface coating quality for you.

Super length easy load into open top container that will avoid deformation, and it is easy unloading goods, saving buyer's labor cost.

Corrugated Perforated Metal Panels

If you need customized wire mesh products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products