PU Modular Screen

If you need customized wire mesh products, Contact US !

Products Category

Tag list

- 产品描述

-

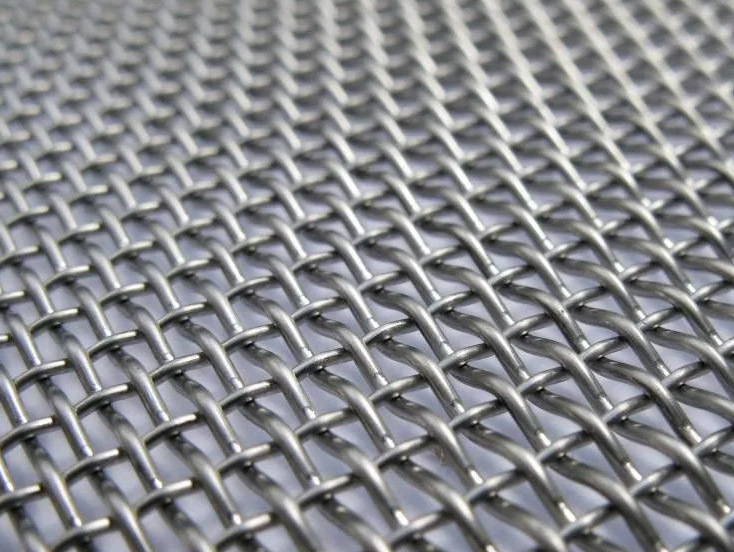

Product Introduction

PU modular screens adopt advanced modular design to ensure excellent screening performance even in high-frequency vibration environments. Each screen module can be independently replaced, significantly reducing the time and cost of screen replacement, which makes it especially suitable for large-area screening. This product is not only suitable for industries such as mining and metallurgy but can also provide customized solutions according to customer needs. Whether your production line requires higher screening accuracy or longer service life, modular screens can perfectly meet your needs, making your production more efficient.

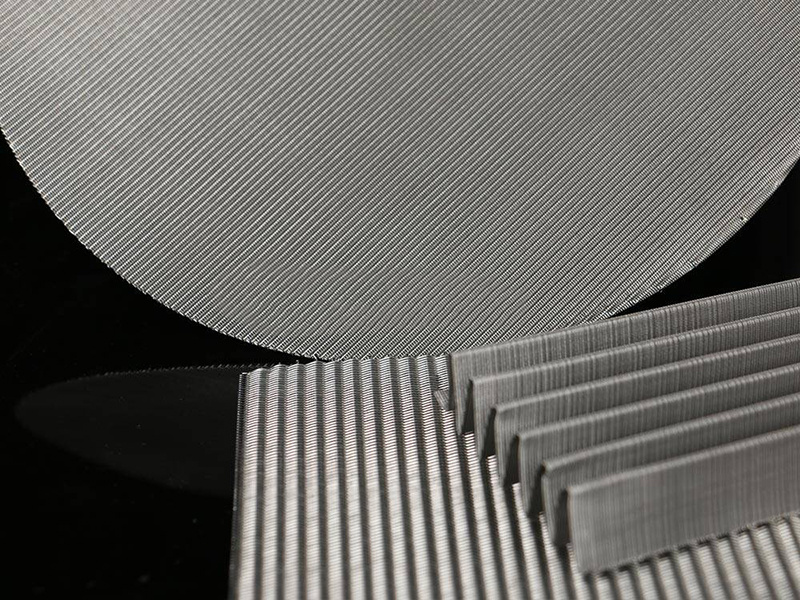

Specifications

Aperture: 0.3 mm – 160 mm (square/rectangular)

Thickness: 30–50 mm

Screen size: Central module 300 mm × 1000 mm, the standard size of external modules is the size of the sifters or sorting equipment

Material: The steel and wire rope performance complies with ISO 630 (GB/T 700) and GB/T 12753 standards; Polyurethane materials are divided into polyester type and polyether type, with specific parameters as follows:

Table 1: Polyurethane Material Parameters No. Inspection item Polyester Type Polyetder Type 1 Hardness/Shore A 80±2 85±2 90±2 95±2 90±2 95±2 2 Tensile strengtd/MPa ≥ 40 ≥ 43 ≥ 46 ≥ 48 ≥ 30 ≥ 40 3 Elongation at break/% ≥ 600 ≥ 580 ≥ 550 ≥ 500 ≥ 400 ≥ 300 4 Tear strengtd/(kN/m) ≥ 70 ≥ 75 ≥ 85 ≥ 100 ≥ 75 ≥ 90 5 Resilience/% ≥ 25 ≥ 25 ≥ 25 ≥ 25 ≥ 35 ≥ 35 6 Relative volume wear/mm3 ≤ 60 ≤ 60 ≤ 60 ≤ 60 ≤ 40 ≤ 40 Special requirements can be customized through negotiation.

Features

● Reinforcing ribs are embedded, which can not only transmits the vibration force of the screen body correctly but also enhance the load-bearing capacity of the screen panel, thereby improving its service life.

● With a modular design, the screen panels can be replaced at will, maximizing the utilization of the screen panels and reducing on-site storage and costs.

● It has excellent wear resistance and shock absorption, high elasticity, and screening accuracy, and can maintain stable screening performance in high-impact working environments.

● The novel buckle structure allows for quick and easy installation and replacement of screen panels while ensuring sufficient connection strength, improving work efficiency and reducing labor intensity.

● According to the screening requirements of the material, different opening shapes can be customized to meet on-site process specifications.

Case Study

Application Fields

PU modular screen uses natural dry and wet screening methods to classify natural materials. It is used to classify, enrich, and dewater crushed materials, coal, ore, coal slag, and other granular materials. Besides, it can also be freely combined with vibrating screens or other mining equipment, suitable for fields such as mines, refineries, and quarries.

PU Modular Screen

If you need customized wire mesh products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products