Zig-Zag Self-Cleaning Screen

If you need customized wire mesh products, Contact US !

Products Category

Tag list

- 产品描述

-

Product Introduction

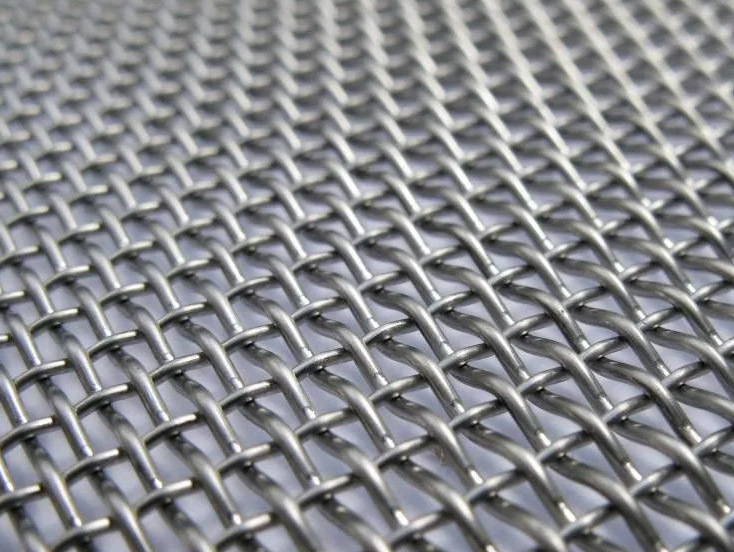

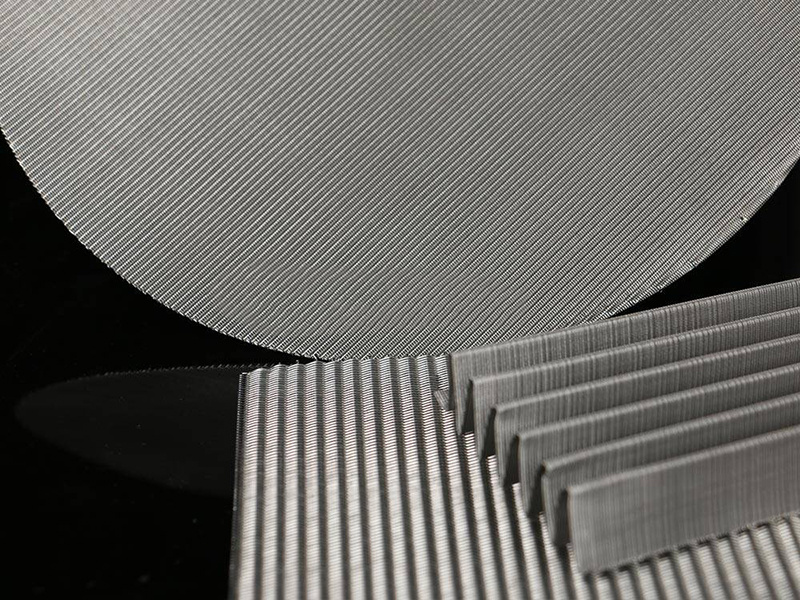

JTD zigzag wire screens are mainly used to filter fine aggregates with high screening efficiency, and also suitable for screening lager dry materials with less sheet-shaped materials. This self-cleaning screen is an ideal solution for wet and sticky materials, ensuring a screening operation free of clogging and pegging. These features make the wire screens especially suitable for separating used asphalt. We strongly recommend the zig-zag self-cleaning screens because of they are very durable.

Features

● Larger wire diameters naturally increase wear-life without significantly sacrificing screening efficiency;

● Rubber or polyurethane cross bands are optional to strengthen the screening surface and vibration stability;

● Suitable for screening fine aggregates, sticky materials or other lightweight but difficult-to-screen materials;

● Opening: 5/64 inch – 3/4 inch;

Specifications

Aperture Width(mm) Wire Diameter(mm) Wire Diameter (inch) Weight/m2 Open Area Material 2.00 1,20 - 1,60 3/64” - 1/16” 3,3 - 4,8 57 - 51 AR/AISI 304/AISI 316 2.50 1,20 - 2,00 3/64” - 5/64” 3,1 - 5,9 60 - 53 AR/AISI 304/AISI 316 3.00 1,20 - 2,00 3/64” - 5/64” 2,8 - 5,4 64 - 57 AR/AISI 304/AISI 316 3.50 1,20 - 2,00 3/64” - 5/64” 2,5 - 5,4 67 - 57 AR/AISI 304/AISI 316 4.00 1,20 - 2,00 3/64” - 5/64” 2,3 - 4,8 70 - 62 AR/AISI 304/AISI 316 4.50 1,20 - 2,00 3/64” - 5/64” 1,9 - 4,5 75 - 64 AR/AISI 304/AISI 316 5.00 1,50 - 2,80 0,059 - 7/64” 2,7 - 8,2 71 - 56 AR/AISI 304/AISI 316 5.50 2,00 - 2,50 5/64” - 0,098 4,1 - 6,2 67 - 61 AR/AISI 304/AISI 316 6.00 1,50 - 2,80 0,059 -7/64” 2,5 - 7,1 73 - 60 AR/AISI 304/AISI 316 6.50 2,00 - 2,50 5/64” - 0,098 3,7 - 5,6 70 - 64 AR/AISI 304/AISI 316 7.00 2,00 - 3,15 5/64” -1/8” 3,4 - 6,4 72 - 67 AR/AISI 304/AISI 316 7.50 2,00 - 3,00 5/64” -1/8” 2,2 - 6,9 62 - 63 AR/AISI 304/AISI 316 8.00 2,00 - 3,15 5/64” -1/8” 3,1 - 6,1 74 - 69 AR/AISI 304/AISI 316 8.50 2,00 - 2,50 5/64” - 0,098 2,8 - 4,25 77 - 73 AR/AISI 304/AISI 316 9.00 2,00 - 3,15 5/64” -1/8” 2,7 - 6,0 79 - 69 AR/AISI 304/AISI 316 10.00 2,00 - 3,15 5/64” -1/8” 2,5 - 5,2 80 - 73 AR/AISI 304/AISI 316 11.00 2,00 - 3,15 5/64” -1/8” 1,9 - 4,9 85 - 75 AR/AISI 304/AISI 316 12.00 2,00 - 4,00 5/64” -5/32” 2,0 - 7,2 84 - 71 AR/AISI 304/AISI 316 12.50 2,50 - 4,00 0,098 -5/32” 3,1 - 7,2 80 - 71 AR/AISI 304/AISI 316 13.00 2,00 - 3,00 5/64” -1/8” 3,3 - 4,3 74 - 71 AR/AISI 304/AISI 316 14.00 2,50 - 4,00 5/64” -5/32” 2,9 - 6,7 82 - 73 AR/AISI 304/AISI 316 15.00 2,50 - 4,00 0,098 -5/32” 3,1 - 6,4 80 - 74 AR/AISI 304/AISI 316 15.50 3.00 0.118 3.80 80 AR/AISI 304/AISI 316 16.00 3,00 - 4,00 0,118 -5/32” 3,9 - 6,4 75 AR/AISI 304/AISI 316 17.00 3,00 - 4,00 0,118 -5/32” 3,8 - 6,2 80 - 75 AR/AISI 304/AISI 316 18.00 3,00 - 4,00 0,118 -5/32” 3,7 - 5,6 80 - 78 AR/AISI 304/AISI 316 19.00 3,00 - 4,00 0,118 -5/32” 3,4 - 5,5 82 - 78 AR/AISI 304/AISI 316 20.00 2,50 - 4,00 0,098 -5/32” 2,2 - 5,2 86 - 79 AR/AISI 304/AISI 316 22.00 3,00 - 4,00 0,118 -5/32” 3,0 - 5,0 84 - 80 AR/AISI 304/AISI 316 24.00 4.00 5/32” 4.80 81 AR/AISI 304/AISI 316 25.00 3,00 - 4,00 0,118 -5/32” 2,8 - 4,7 85 - 81 AR/AISI 304/AISI 316 27.00 4.00 5/32” 4.20 83 AR/AISI 304/AISI 316 28.00 4.00 5/32” 4.10 83 AR/AISI 304/AISI 316 30.00 3,00 - 4,00 0,118 -5/32” 2,2 - 3,8 87 - 85 AR/AISI 304/AISI 316 35.00 4,00 - 5,00 5/32” -13/64” 3,4 - 5,2 86 - 83 AR/AISI 304/AISI 316 40.00 4.00 5/32” 2.70 89 AR/AISI 304/AISI 316 45.00 4.00 5/32” 2.50 90 AR/AISI 304/AISI 316 ● AISI 304L / EN 1.4307: Austenitic stainless steel with low carbon content.

● AISI 304 / EN 1.4301: High resistance austenitic stainless steel.

● AISI 316 / EN 1.4401: Austenitic stainless steel with molybdenum to strengthen corrosion resistance.

● AR / EN 10270: Wear resistant steel with a high content of carbon and manganese.

● NUBA Screening Media, at the customer’s request can provide a Quality Inspection Certificate (compliant with EN 10204.3.1.B) showing the chemical and mechanical properties of the materials. Other aperture/wire combinations and materials such as galvanized steel etc. are available at customer’s request.

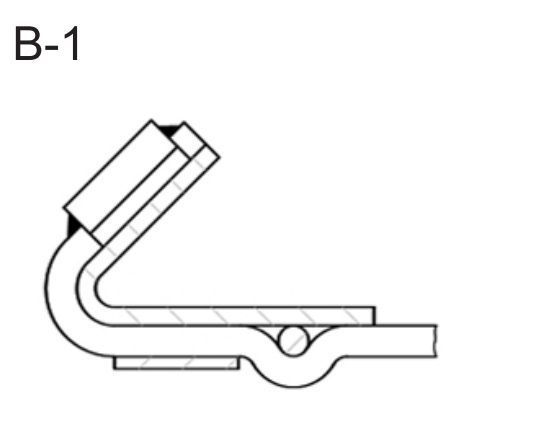

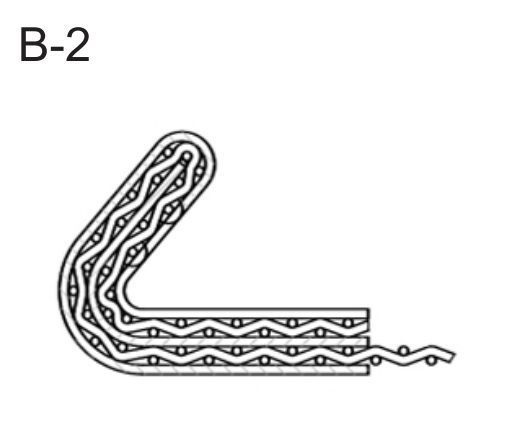

Self-cleaning screen hook strip styles

Zig-Zag Self-Cleaning Screen

If you need customized wire mesh products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products